We recommend using your Cytostretcher Chambers within 2 years of purchase.

Read MoreAs with any cultureware, optimal seeding density on Curi Bio Cytostretcher Chambers can vary according to cell type and the purpose of the experiment. However, we recommend researchers use the same cell density that they would use for conventional cultureware. For specific applications, please contact us at support@curibio.com.

Read MoreFor most commercially available cell lines, the cell seeding density used on conventional cultureware works with Curi Bio Cytostretcher Chambers as well. If you are using your own cell line, our support team can provide you with suggestions on how to design seeding density optimization experiments.

If you require additional support, please contact support@curibio.com so that our applications team can provide you with the relevant suggested protocol.

Read MoreWe recommend coating the surface with the extracellular matrix protein you typically use in your cell culture workflow (collagen, fibronectin, gelatin, Matrigel, etc.). We also have a suggested concentration in our manual for protein coating of our substrates using some of these proteins. Before starting your experiments, make sure to check our manuals where you can find the details of the protocols for each protein coating.

Read MoreNo, all Curi Bio Cytostretcher chambers need to be sterilized and protein coated following the suggested steps in this manual and prior to cell plating.

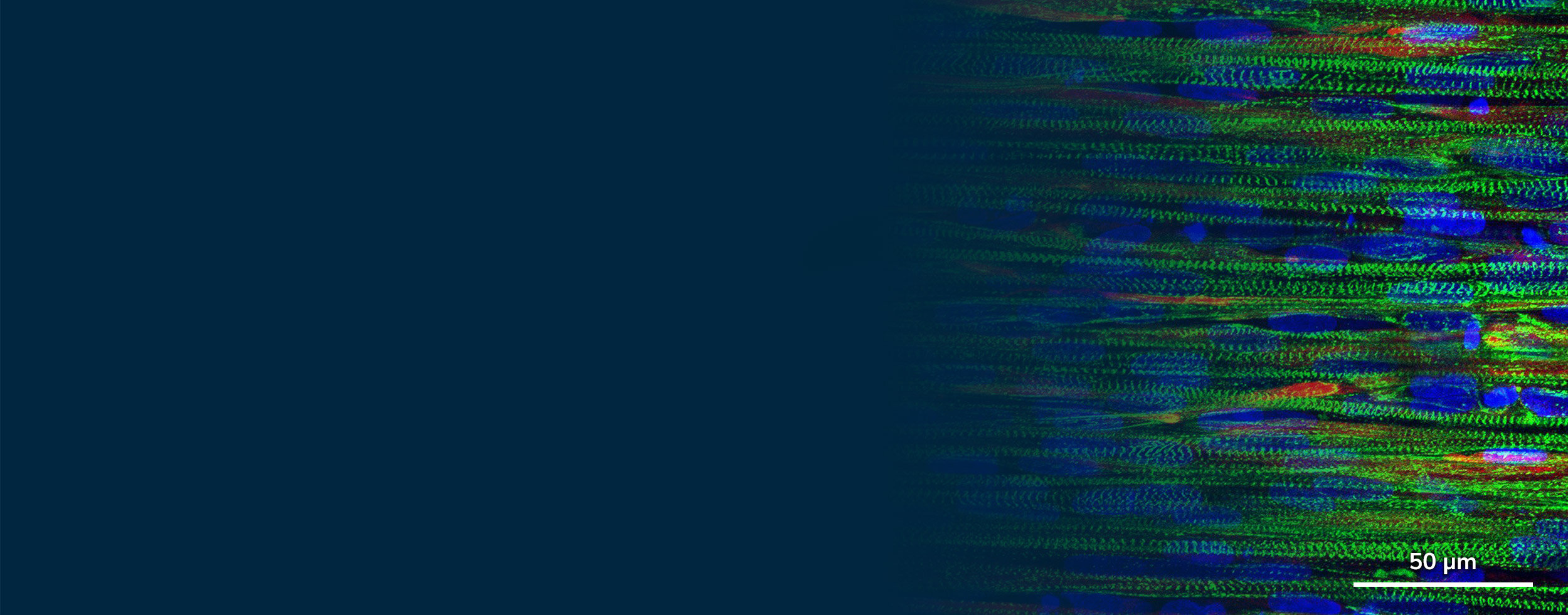

Read MoreCytostretcher Chambers come in: (1) unpatterned "flat" and (2) NanoSurface topography. Both formats have a polymer substrate that is softer than conventional glass or plastic cultureware. As a result, the softer substrates are more representative of the mechanical properties of the tissue microenvironment. The NanoSurface substrate possesses submicron grooves with a feature size that is comparable to the collagen microenvironment in the body. As a result, the pattern is also optimized to be in the size of the focal adhesion of cells and facilitate the alignment of adherent cells. Our customers usually use flat substrates either for their improved mechanical properties (softer substrate) or as a control sample for NanoSurface topography to show the differences in the functionality of aligned and non-aligned tissue.

Read MoreThe substrate thickness is specified at 160--190 microns (0.16--0.19 mm). This is the same thickness specification as a No. 1.5 coverglass. The polymer has an index of refraction comparable to that of glass.

Read MoreThe Cytostretcher is capable of applying maximum of 5Hz frequency.

Read MorePlasma treatment is one of the more effective methods for adequate surface modification. If you do not have access to a plasma machine in your lab, you can also use PDL coating. Please refer to our manual or contact our support team for details of each protocol.

Read MoreThe surface of the Cytostretcher chambers is hydrophobic by nature. To allow for faster and better adsorption of the proteins onto the surface, you will need to perform surface modification (physical or chemical) making the chamber substrate hydrophilic prior to use.

Read MoreWe strongly suggest not to reuse the Cytostretcher chambers as the cleaning and reusing process may obscure or damage the substrates.

Read MoreWe recommend storing Cytostretcher Chambers where they are protected from light and under climate controlled conditions (Ex. 20-25 degrees Celsius, 30-50\% humidity).

Read More